From Planning To Production: How We Do Things At Rubber Box

Unless you’re an old hand in the electrical engineering industry, it can sometimes be a little difficult to know what to expect when beginning your search for the perfect power distribution system. At Rubber Box, we always like to help out where we can, so this week we’re providing you with a bit of insight into how we get things done – just so you know what to expect when you get in touch.

How It Starts

Like almost any business, it all starts with an enquiry. Depending on the client’s technical ability, sometimes it’s furnished with ready-made requirements and specifications, but it’s rarely a problem if it’s not. We then get in touch with the customer in order to collect some basic information about the project – namely its estimated power usage in specific terms, a rough layout of the site, and if we can, information about the currents, voltages, and generators. From there we can work out pivotal things like how much power our system will provide and what cabling is most suitable, so that we can advise on the most appropriate power distro to use.

What We Do

We use these key pieces of information to determine the equipment we would recommend, which will determine the number and type of outlets in the power distribution system. From there, we concentrate on making things safe. Operating to strict national engineering regulations, we install overload protection and earth leakage protection in all of our products. To briefly explain, overload protection is exactly what it sounds like – in the event of an overload it disconnects the power, thereby preventing the device from short-circuiting, damaging itself or harming you. Earth leakage protection is commonly referred to as ‘the lifesaver’. It measures the current running through the live and the neutral, and keeps it balanced. If it detects an imbalance that could potentially be unsafe, it interrupts the circuit and disconnects the power. We install these as standard, although some clients specify further – sometimes bespoke – safety measures which we make on demand.

Once we have all the information we need, we can make an accurate assessment of all the different factors involved, and then come back to the client with a quote for the recommended system. The next stage is for the client to place an order, at which point we will build the system (sometimes working to tight deadlines) and ship it directly to them.

But It Doesn’t Stop There

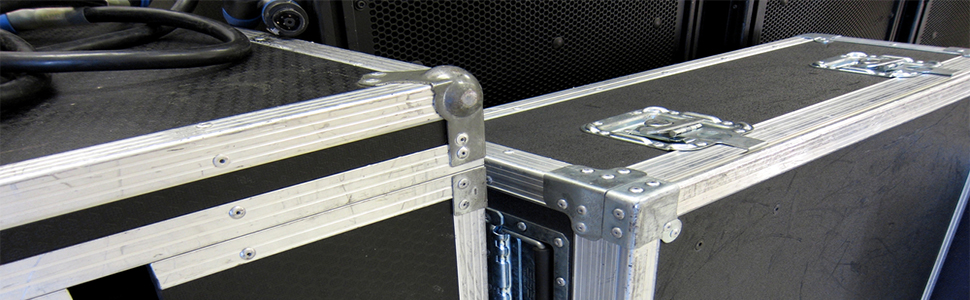

Rubber Boxes’ power distribution boxes are portable, specifically designed to be easy to install, and subsequently move around. Our customers in the music industry especially often require systems which can be quickly set up and taken down again, ready to be taken to the next venue. After the sale, we offer ongoing technical support to all of our clients free of charge – it’s all part of the service. Almost all problems that we’re contacted with can be solved over the phone, without necessitating a potentially costly on-site visit.

That’s all there is to it! No matter your project requirements or level of technical knowledge, our expert engineers are here to help. You can to browse our range of power distribution boxes, or get the ball rolling now by requesting a quote.

Don’t forget to follow us on Twitter: @Rubberbox