5 signs it’s time to upgrade your power distribution boxes

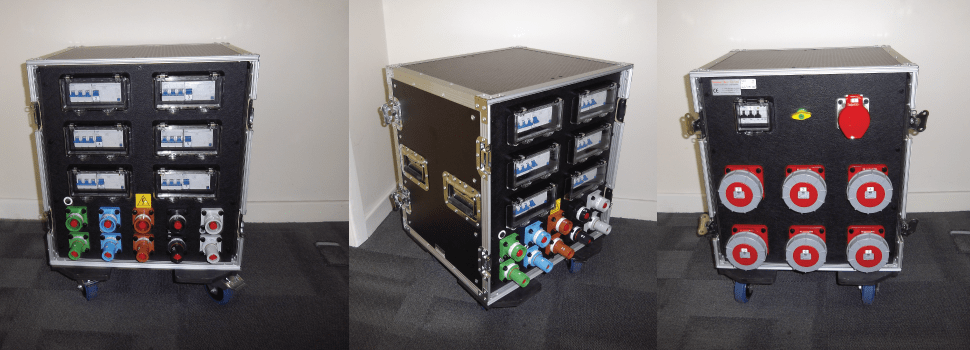

Power distribution boxes are the backbone of any reliable electrical setup. Whether you’re powering a lighting rig, running equipment on-site, or managing a busy production schedule, safe and stable power is something you should never have to second-guess. Without it, even the most well-planned operation can quickly come to a standstill.

At Rubber Box, we’ve spent more than two decades building distribution units that crews and organisations rely on every day, in all kinds of environments. If you’re working with older, legacy or heavily-used power distribution equipment, being able to recognise early warning signs gives you the chance to plan ahead and replace equipment on your own terms, rather than in the middle of a job. With that in mind, here are five key indicators that a distribution box might be nearing the end of its working life.

1. Visible wear and tear on the casing

A power distribution box’s casing does far more than simply hold everything together; it’s the first line of defence against impact, moisture, dust and general site conditions. Over time, especially with frequent transport between jobs or heavy use in outdoor environments, the enclosure can start to show signs of deterioration. This can often be subtle at first, with minor scuffs or discolouration, before progressing to more noticeable issues.

Look out for:

– Cracks or brittle areas on the casing

– Warping, discolouration or UV damage

– Loose fittings or weakened handles

– Damaged seals that allow moisture or dust inside

A strong enclosure helps maintain the unit’s IP rating and ensures the internal components are properly protected, which is vital for safe operation. Once the casing is compromised, even slightly, it becomes more susceptible to environmental damage. If a distribution box can no longer provide a solid, dependable barrier, it’s usually a sign that an upgrade is the safest way forward.

2. Frequent RCD or breaker trips

Every distribution box is designed to trip when necessary; it’s a core safety feature. But when trips start happening under normal load, with no apparent cause, it can be a sign that something internally is no longer functioning as it should. Over time, breakers and protective devices can weaken, wiring connections may loosen, and components exposed to heat or consistent strain can degrade. These things often happen gradually, making it easy to overlook the severity at first.

You may notice:

– Breakers tripping with light or moderate usage

– RCDs behaving inconsistently or not resetting smoothly

– Equipment is cutting out without a clear cause

While replacing breakers or components can help in the short term, repeated issues usually point to an underlying problem. At a certain point, continually repairing an ageing unit becomes less efficient, and often less safe, than replacing it with a modern, fully reliable alternative.

3. Phase imbalance or unstable output

In three-phase systems, balanced output isn’t just desirable, it’s essential for ensuring connected equipment runs smoothly and efficiently. When a distribution box starts struggling to maintain that balance, it can put stress on both your equipment and the electrical system itself. Older units, in particular, may not handle today’s more sensitive or power-hungry gear as well as they once did.

Common signs include:

– Uneven load readings across phases

– Flickering or underperforming equipment

– Overheating neutral conductors

– Voltage irregularities are shown on the testing equipment

Phase imbalance can be caused by wiring degradation, outdated internal layouts, or simply wear from years of service. If the imbalance continues even after careful load planning, this often suggests that the distribution box is no longer performing at the standard required and may need upgrading to maintain safe, consistent power.

4. Outdated connectors or insufficient capacity

Standards in the electrical and event industries evolve over time, and equipment demands evolve with them. A distribution box that was perfectly adequate a decade ago may now be limited simply because modern equipment requires different connectors, higher capacity or more advanced protection. These limitations typically become clear during setup, as more and more workarounds are needed to make the older unit fit current requirements.

You might notice:

– Socket types that are no longer commonly used

– Reliance on adapters to fit modern equipment

– Limited capacity compared to your current needs

– No space for up-to-date protection devices such as RCBOs or surge protection

Working around an outdated unit can slow down setups and increase the risk of faults. Upgrading ensures your distribution box supports modern equipment safely, efficiently and without compromise, helping your team work more smoothly on-site.

5. Heat, noise or unusual smells

Some warning signs are subtle, but others make themselves known the moment you get close to the distribution box. Excess heat, buzzing, or an unusual electrical smell are all indicators that something inside the unit is under strain, often significantly so. These can stem from worn components, failing internal connections or overheating caused by age or repeated use.

Pay attention to:

– Hot spots on the casing

– A persistent electrical smell

– Buzzing or humming noises

– Signs of scorching around sockets

These symptoms should never be ignored. Even if the box still appears to be functioning normally, it often signals the beginning of a more serious issue. Tackling the problem early, ideally by planning an upgrade, helps prevent unexpected downtime and protects both your equipment and the people working around it.

For over 20 years at Rubber Box, we’ve supported events, venues and industries across the UK and in more than thirty countries worldwide. Our power distribution units are built to order, extensively tested, and trusted by teams who rely on their equipment day in and day out.

If you’d like advice on whether it’s time to upgrade your power distribution equipment, we’re always happy to help. Give us a call on 01282 677 910 or email info@rubberbox.co.uk to speak with one of our experts and get friendly, informed guidance tailored to your setup.