Why cable choice matters more than people think

Cables are easy to overlook. They are often the last thing specified on a job and the first thing people grab without much thought, as long as it fits. In reality, cable choice plays a huge role in how safe, reliable, and efficient your power distro setup really is, especially in environments where loads are high and conditions are far from gentle.

From live events and touring rigs to film sets, exhibitions, and industrial installs, the right cable can prevent downtime, reduce risk, and make setups faster and more dependable. The wrong one can do exactly the opposite. With that in mind, here’s why cable choice matters far more than people often realise.

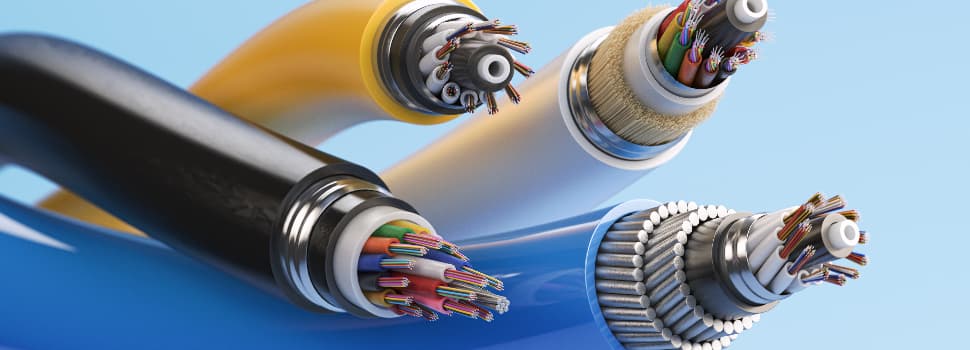

Cables are not just connectors

Every cable in a setup is responsible for carrying electrical load safely from the source to the equipment. That means it must be correctly rated for the current, the length of the run, and the way it will be used.

Using a cable that is not suitable for the load can lead to voltage drop, overheating, or premature wear. These risks increase as current levels rise. Rubber Box supplies cables across a wide current range, from 16A through to 400A, in both single-phase and three-phase options, enabling systems to be built with cables that match the demands placed on them.

The environment has a big impact on cable performance

Temporary power environments are rarely gentle. Cables are frequently handled, coiled, uncoiled, and routed through busy areas. They may be laid across floors, passed through cable protection, or used in spaces where equipment is constantly being moved.

For these applications, heavy-duty cable construction is essential. The cables used across events and temporary power installations are designed to withstand repeated handling and mechanical stress far better than light-duty alternatives. Choosing a cable that suits the environment helps reduce damage, extend service life, and maintain safe operation throughout a project.

Correct sizing helps avoid long-term issues

Cable length and conductor size are closely linked and should always be considered together when planning a power setup. As cable runs get longer or current levels increase, using the correct size helps maintain stable performance and manage heat within the cable over time.

If a cable is undersized for its application, problems may not be immediately obvious during setup. Gradually, voltage drop and excess heat can begin to affect connected equipment and reduce overall reliability. This is particularly important if you’re working with higher current supplies like 63A, 125A, or 400A, or when using Y cords to split power across multiple outputs.

Compatibility keeps installations simple and reliable

Cables are part of a wider power system that includes distribution equipment, connectors, and protective accessories, all of which need to work together smoothly. When components are well matched, installations are easier to build, easier to understand, and far less prone to errors during setup or operation.

Using cables that are designed to work alongside distribution equipment helps keep systems organised and logical from the outset. Connections are clearer, routing is more straightforward, and it becomes easier to see how power is flowing through the system. This is particularly important on busy sites where multiple supplies and outputs are in use at the same time.

Good compatibility also makes systems easier to adapt. If requirements change or a fault needs to be traced, clear and consistent cable and connector choices reduce guesswork and speed up fault finding. In fast paced environments, this clarity will help your crews work more efficiently while maintaining safe and reliable power distribution.

Choosing the right cable is easier with expert advice

Choosing the right cable is not always as simple as it seems. Once you start factoring in current, phase, length, and how the cable will actually be used on site, it quickly becomes clear that small decisions can have a big knock-on effect later.

That is where a bit of experience really helps. At Rubber Box, we spend a lot of time talking through setups with customers, often because something didn’t quite work as expected on a previous job. Sometimes it is about choosing a different cable size, sometimes it is about how everything connects back to the power distro unit. Those conversations are often what make the difference between a setup that just works and one that causes problems under pressure.

Cable choice might not be the most obvious part of a power system, but it plays a big role in how smoothly everything runs. Getting it right makes setups easier to manage, faults easier to track down, and the whole system more reliable from the start. If you are planning a new setup or just taking another look at what you are already using, you can browse our full range of cables and accessories here on our site. Or, if you would rather talk it through, you can also give your friendly team a call on 01282 677 910 or send us an email to info@rubberbox.co.uk for advice.